The desired dose distribution in superficial tumors is difficult to guarantee due to the skin-sparing effect of megavolt photons. Therefore, a bolus is placed at superficial irradiation areas to shift the build-up effect and get the desired dose into the surface of the target area. At the moment, personalized boluses are still often made by hand. The result of this is not always satisfactory in terms of fit (air-gaps) and reproducibility. In addition, it is often a time-consuming process because the hardening of molds and bolus takes a relatively long time. The ADAPTIIV 3D printing software solution makes it possible to create patient-specific boluses for photon and electron beam treatment, as well as high dose rate (HDR) surface brachytherapy applicators, printed directly from a 3D printer. The ADAPTIIV software solution integrates directly with existing scheduling software.

The Adaptiiv 3D solution consists of software, hardware and printed materials.

The software can convert DICOM data taken from patient CT scans and turn them into a digital model that can be printed, no matter how large, small or complex. There is no intensive training required to use our software enabled solution which fully integrates with most existing treatment planning systems.

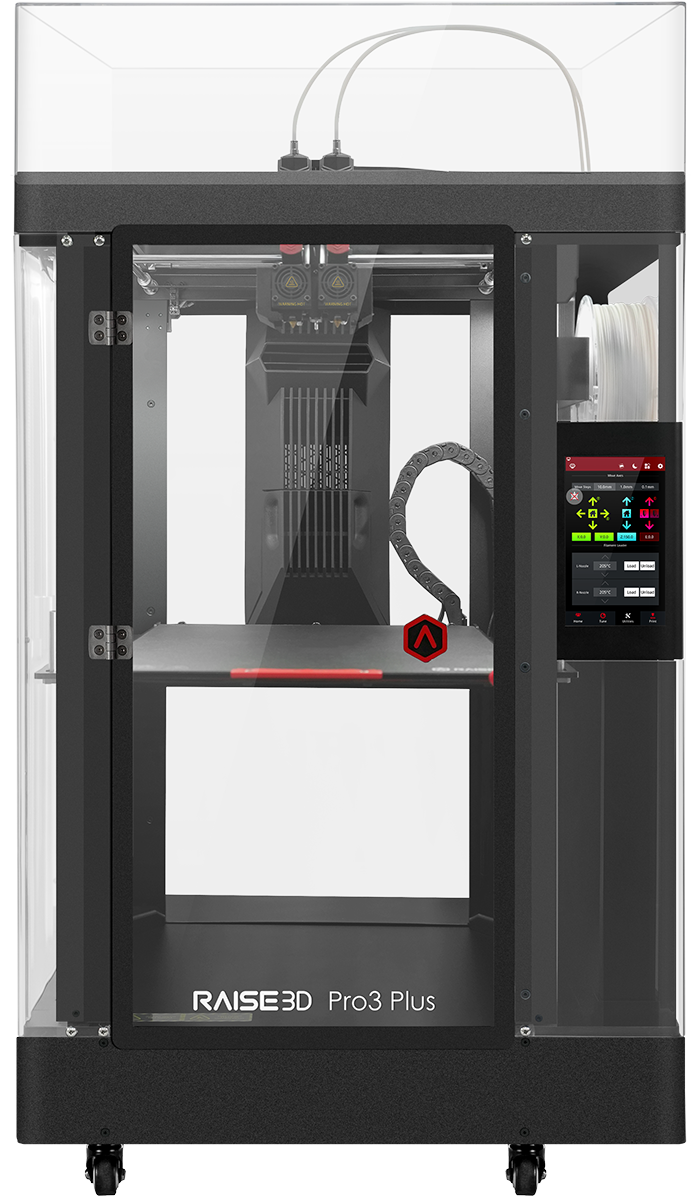

Adaptiiv recommends the Raise3D Pro2 Plus series printer. By using this printer there is no need for centers to outsource patient data in order to create devices. They are able to care for patients in-house immediately and adapt treatment changes quickly.

3D boluses are created to conform perfectly to individual body shapes. The filaments are made from polylactic Acid (PLA), a bioplastic from vegetable source. The material is available in different colors, rigidities, and densities.

Three different models can be produced with different densities and flexibilities.

Designed in the treatment planning system for use with photon or electron radiotherapy. The custom-fit can eliminate air gaps, improving treatment accuracy.

A custom, optimized bolus design that provides modulation of the electron beam to conform the prescription isodose to the PTV, sparing the underlying normal tissue.

Allows users to create specific applicators that hollow catheter trajectories printed directly into the structure. This highly customizable surface applicator provides an optimal dose distribution.